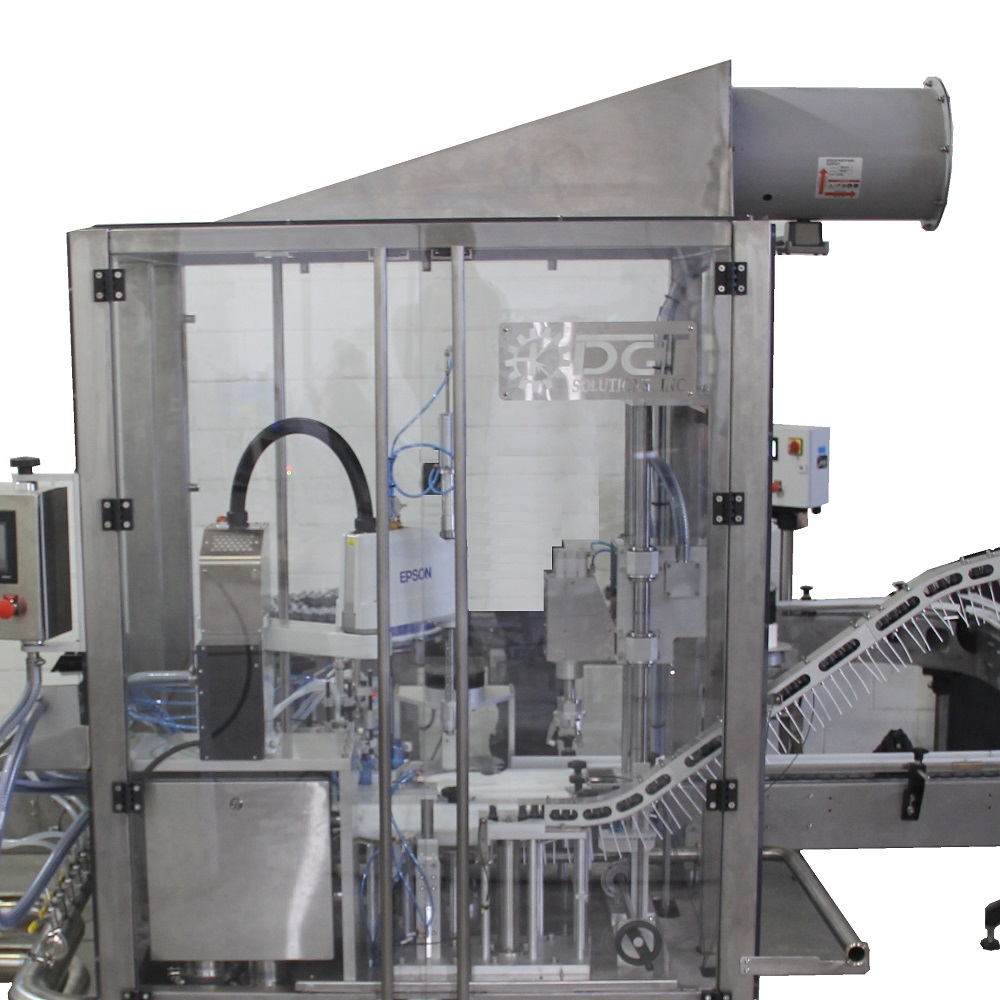

Filling-capping monobloc machines

Automated processing equipment

Filling-capping monobloc machine for liquid filling and capping of a variety of liquid products, including among others essential oils, sanitizers, and disinfectants. In order to choose the most effective and reliable filling machine for your application, several factors must be taken into consideration, such as the viscosity of the product, container shape, material, and closure type.

Request A Quote